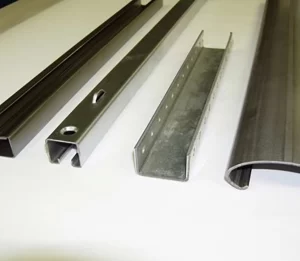

Roll Formed Stampings

Roll Formed Metal Components

D.E. Lehmkuhl & Assoc. manufactures roll formed metal components to provide long, uniformly-shaped metal parts with tight tolerances. We shape long strips or coils of sheet metal by passing them through a series of rollers that slowly bend the metal into the desired shape. Because roll forming happens at room temperature, it avoids any risks of distortion faced by hot forming techniques. The lack of heat application also makes it an energy efficient process, more easily allowing for large quantity production.

Capabilities

- (14)- 1.5″ Roll Mill Lines

- (4) – 2.0″ Roll Mill Lines

- (12) Welders — allowing for in-die welding tasks

Applications

- Automotive Glass & Decorative Trim

- Industrial

- Appliance

- Furniture

Value-Added

- Tape application

- Flocking

- Felt Application

- E-Coat

- Zinc Plating

- Powder Coat

- Plastisol Dip

- Wash and Seal

- Black Oxide

Materials

- Cold / Hot Rolled Carbon Steel

- Stainless / High Strength Steel

- Galvanized / Pre-coated Material

- Aluminum

- Copper

- Brass