Plastic Injection Molded Parts

Plastic injection molding requires tight tolerances that D.E. Lehmkuhl & Assocs. meets to manufacture products meeting your exact specifications. Even the smallest misalignment can cause problems with plastic molded parts. So, we use state-of-the-art technology and techniques to ensure the perfect product for every project.

Capabilities

- Straight Molding

- Insert Molding

- Horizontal Molding (22-350 ton)

- Vertical Molding (35-110 ton)

- State-of-the-Art Electric Molding Machines

Applications

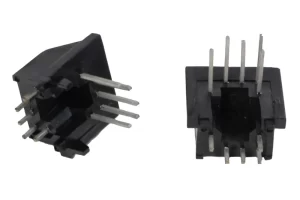

- Electrical Mechanical Assemblies

- Engine & Transmission Components

- Multi-pin Connectors

- Filter Assemblies

- Lead Frames

- Reel to Reel Molding

- And more…

Value-Added

- Automation

- Hi-pot testing

- water jet Capabilities

- Tape and Reel Packaging

- Special packaging

- In House Tool Room

Materials

- PE

- PP

- PBT

- ACRYLIC

- ABS

- ACETAL

- NYLON-STRAIGHT TO GLASS FILLED

- POLYMER BOUNDED MAGNETS

- PPE

- POLYCARBONATES

- TPV