Progressive Metal Stampings

The Progressive Metal Stamping Process

Progressive die stamping, also known as prog die stamping, offers another metal stamping process that works for a variety of industries. This process provides faster production speeds, reduced scrap, and the ability to create complex geometries in a single operation. This makes it suitable for high-volume, cost-effective manufacturing.

Capabilities

- Press Sizes — from 10-800 ton

- Machine Speeds — from 80-1500 strokes per minute

- Prototype Capabilities — Chemically Etched, Photo-Etched, Laser Cut, Wire-Burned, Short Run Tooling and 3D Printer and Water Jet Technology

Applications

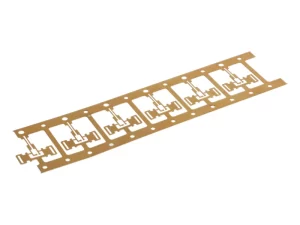

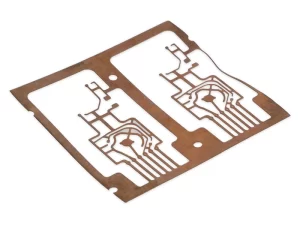

- Stamped Circuits & Lead Frames

- Terminals

- Heat Shields

- Brackets & Ground Plates

- Electrical Contacts & Clips

- Interts & Limiters

- And more…

Value-Added

- Reel to Reel stamping

- Tape & Reel packaging

- Welding

- Assembly

- Heat Treat

- Plating

- Taping, Flocking, Felt

Materials

- Cold / Hot Rolled Carbon Steel

- Stainless / High Strength Steel

- Galvanized / Pre-coated Material

- Aluminum

- Copper

- Brass